ARM Featured in SWANA’s “The Keystone” 2014 Winter Edition

ARM Group was featured in SWANA’s “The Keystone” 2014 Winter Edition for Presenting the Lanchester Landfill Mini-Technology Seminar. See Full SWANA 2014 Winter Newsletter

On November 7, 2013, the SWANA Keystone Chapter held a Mini-Technical Seminar at the Lanchester Landfill in Narvon, PA. Presentations at the seminar were made by Bob Watts, Executive Director of CCSWA, William Tafuto, P.E. of ARM Group Inc. (ARM), and Daniel Fellon, P.E. of ARM. A follow-up presentation of this seminar was attended by Mr. Christopher Abruzzo, Secretary of the Pennsylvania Department of Environmental Protection (PADEP), and Mr. Dana Aunkst, Executive Deputy Secretary of PADEP, on November 25, 2013.

The Lanchester Landfill (Lanchester), an approximately 630-acre disposal facility that has operated since the 1960’s, is owned and operated by the Chester County Solid Waste Authority (CCSWA). The Area E expansion was permitted in 2011, providing approximately 4.1 million tons of capacity at Lanchester, and encompasses a total footprint of approximately 55.9 acres; 41.6 acres of the expansion footprint are comprised of overfilling or a “piggyback” of the existing landfill. The final phase of the initial 3-phase build-out, the Stage 2 Construction project, is currently underway. Final design tasks of the three construction phases to develop the initial cell of the Area E expansion were completed by ARM.

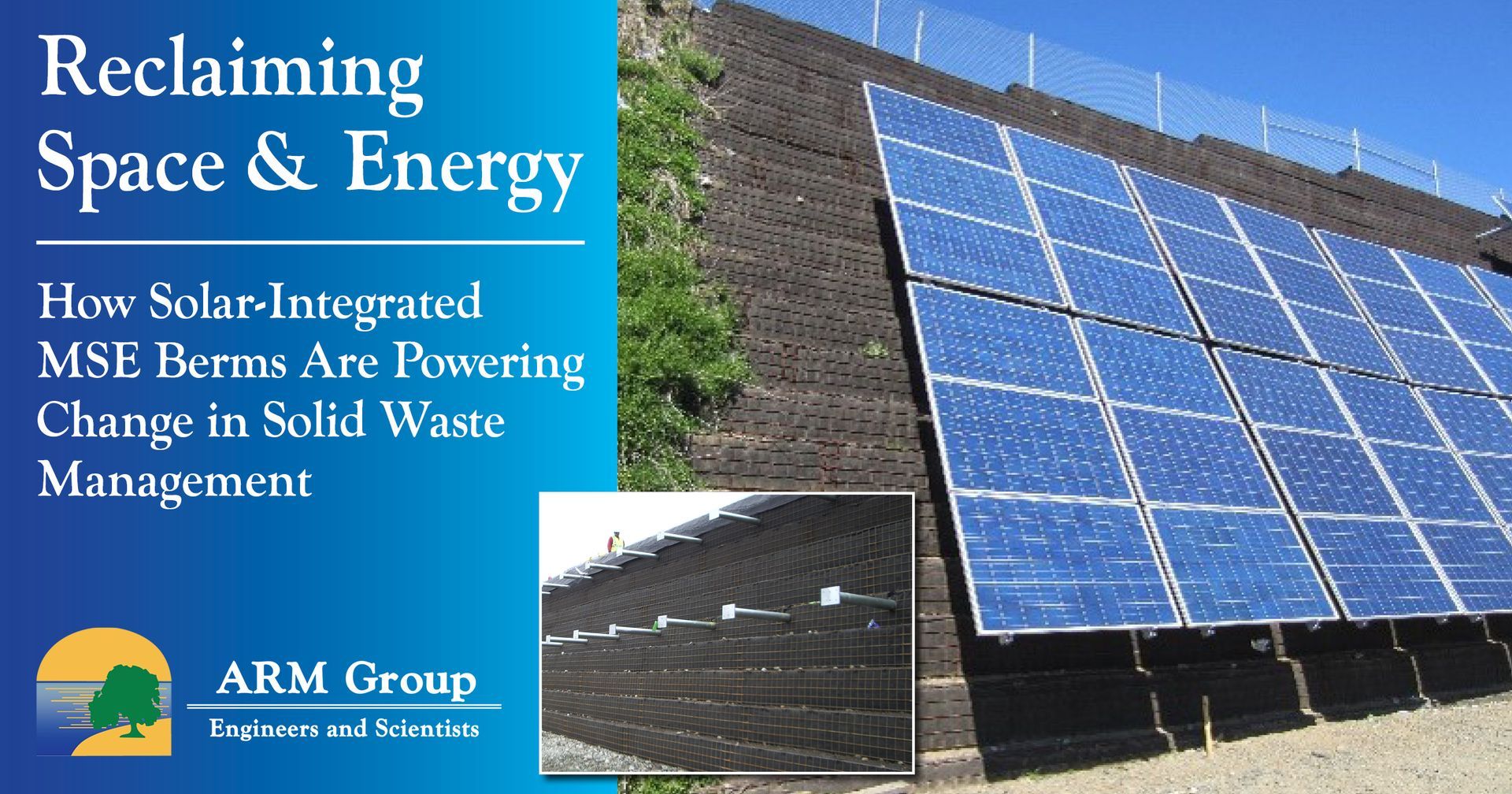

The Stage 2 project includes construction of approximately 1, 600 feet of a mechanically stabilized earth (MSE) berm, the 18-acre liner system for Cell 1 of the expansion, extensive landfill gas (LFG) and stormwater management modifications, and final cover system removal. The MSE berm is constructed to a 1H:3V exterior face, graded with a 2H:1V interior slope, and rises to a maximum height of 68 feet. To date, the MSE berm has been constructed to a height of approximately 47.5 feet.

Construction of MSE berm to 47.5’ of proposed 68’ total height.

Christopher Abruzzo, PADEP Secretary, at Lanchester Landfill Area E Expansion MSE Berm

Preparatory construction phases during the 2011-2013 construction seasons included the following tasks:

- Enlargement of Ponds 1 & 3 – 220, 000 CY of excavation & regrading;

- Onsite screening/crushing of 153, 000 CY of soil materials;

- Decommissioning Ponds 4, 5, and 5A – 110, 000 CY of structural fill;

- Relocation of existing communications/power infrastructure;

- Relocation of the existing LFG flare station;

- Installation of 3, 200 LF of stormwater diversion culverts;

- Slip-lining 2, 300 LF of existing gravity leachate collection pipe;

- Mining/relocation of 31, 000 CY of historic (unlined) waste materials;

- Redirection of 3, 150 LF of existing leachate forcemain;

- Relocation and construction of a 5-acre yard debris Compost Area; and

- Installation of 13, 250 LF of LFG header and lateral piping.

Concurrent with the construction of Area E Cell 1 is installation of an alternative final cover, comprised of the ClosureTurf™ system. ClosureTurf™ is a synthetic HDPE grass-blade product that combines the use of an Agru Super Gripnet® LLDPE geomembrane barrier with a synthetic turf drainage layer component. The double-layer woven geotextile component housing the turf product is subsequently in-filled with sand ballast. The CCSWA permitted the installation of the ClosureTurf™ system as a PADEP Demonstration Project in September 2011 and commenced construction in 2013. A two-year evaluation program will be implemented during 2014-2016 by the CCSWA to document the alternative cover system’s effectiveness in achieving PADEP performance standards , prior to review and further consideration by PADEP as a potential permanent cover system.

ClosureTurf™ installation prior to terrace scour protection and stabilization.

Tours of the active construction projects at Lanchester followed the project discussions.

For more information on these projects, contact Daniel Fellon, P.E., Project Manager at dfellon@armgroup.net.