Smart, Space-Saving Solutions for Waste Facilities

Maximizing Land Use with MSE Berms

In the world of waste management, stability, efficiency, and space optimization are non-negotiable. Whether you're planning a new landfill cell or upgrading a transfer station, the structures you build need to perform—and last.

What if the berms you’re already building could help you save space, cut costs, and meet regulatory goals—all at once?

That’s where mechanically stabilized earth (MSE) berms come into play.

What Are MSE Berms and Why Do They Matter?

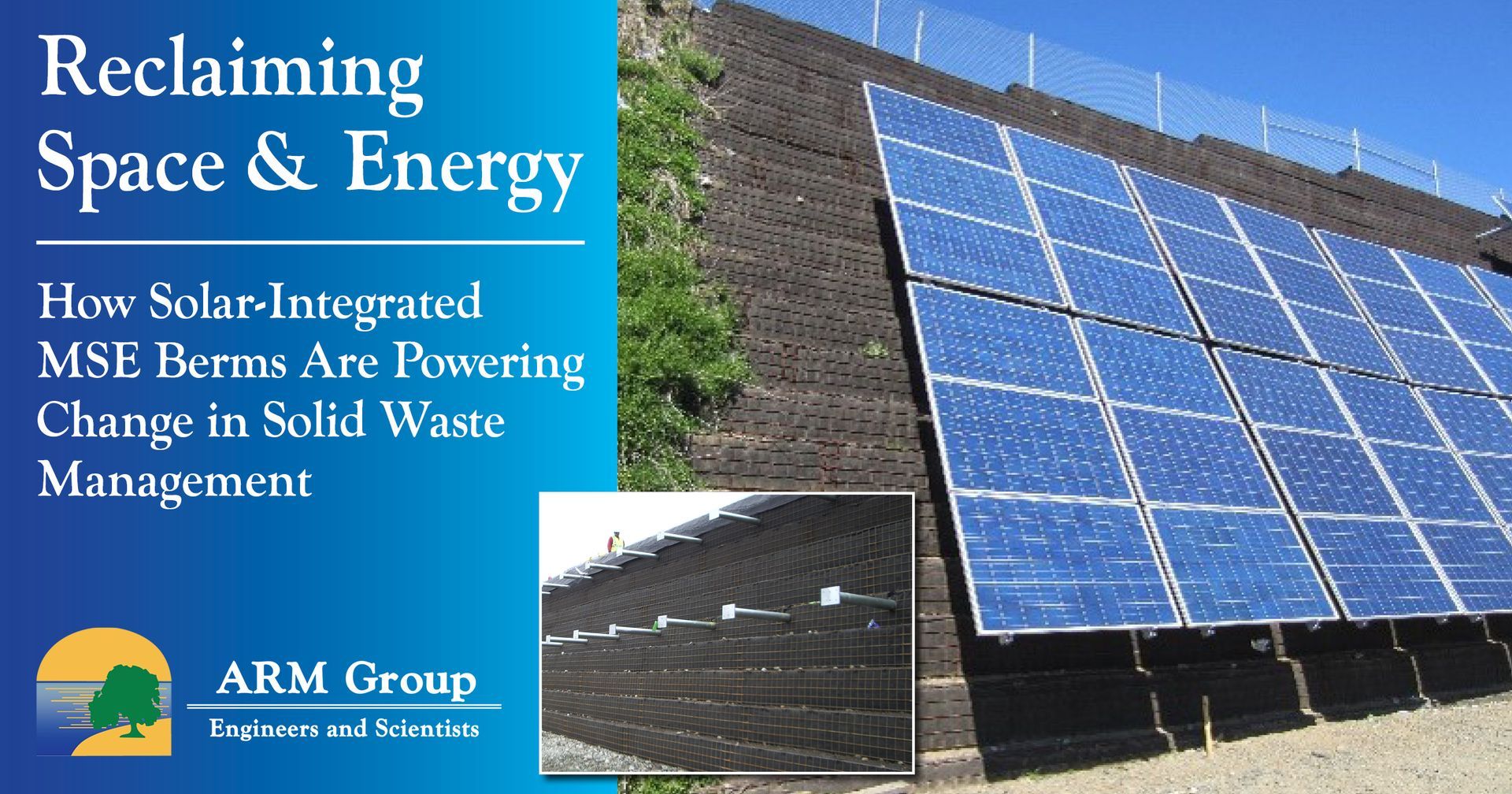

MSE berms are engineered structures that combine compacted earth with reinforcement (typically geogrids) to create a stable, steep-sided embankment. For waste facilities, they offer a smart, space-saving solution that supports both operational goals and regulatory requirements.

Why Use MSE Berms?

Unlike traditional earth berms or natural slopes, MSE berms are designed to retain earth at much steeper angles—meaning they take up less horizontal space while still offering the same (or better) structural support. For solid waste facilities, that translates into more usable land for operations, waste placement, or expansion.

How MSE berms benefit waste facilities:

- Maximize Land Use

By building vertically, MSE berms allow facilities to conserve valuable site area. This is especially important for land-constrained sites or urban operations. - Support Landfill Expansions

MSE berms are frequently used to raise landfill grades or create containment structures for new disposal cells. Their engineered design provides long-term stability, even under heavy loads. - Cost-Effective and Durable

Compared to cast-in-place retaining walls or concrete structures, similar to what is seen along highways, vegetated MSE berms often require less material and labor, and can be built using onsite soils when appropriate or alternative backfill materials.

Key Applications at Waste Sites:

- Perimeter Containment: Create physical boundaries for landfills with minimal space impact.

- Roadway and Access Support: Elevate haul roads or access ramps without compromising slope stability or requiring significant footprint.

Design Considerations

Every site is different, and MSE berm design needs to account for factors like:

- Soil type and compaction

- External loads (e.g., waste mass, vehicles)

- Drainage and water management

- Seismic considerations

- Longevity and maintenance needs

- Site access requirements

Isn’t it time your infrastructure worked a little harder for your site?

ARM Group is here to work closely with clients to develop custom MSE berm designs that meet both performance goals and regulatory requirements. Our team brings together geotechnical, civil, and environmental expertise to ensure each berm is not only structurally sound but also optimized for the realities of your site.

Click here to learn more about our services.

Get More Life out of Your Facility

Whether you’re building new infrastructure or improving existing operations, MSE berms offer a proven, flexible solution for waste management facilities. Contact ARM Group to explore how our engineered berm designs can support your next project.